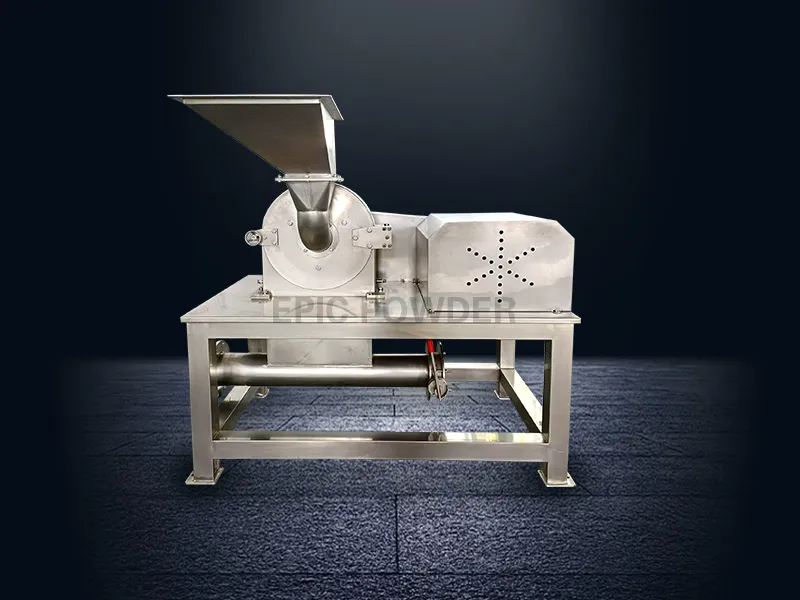

Working Principle and Equipment type features

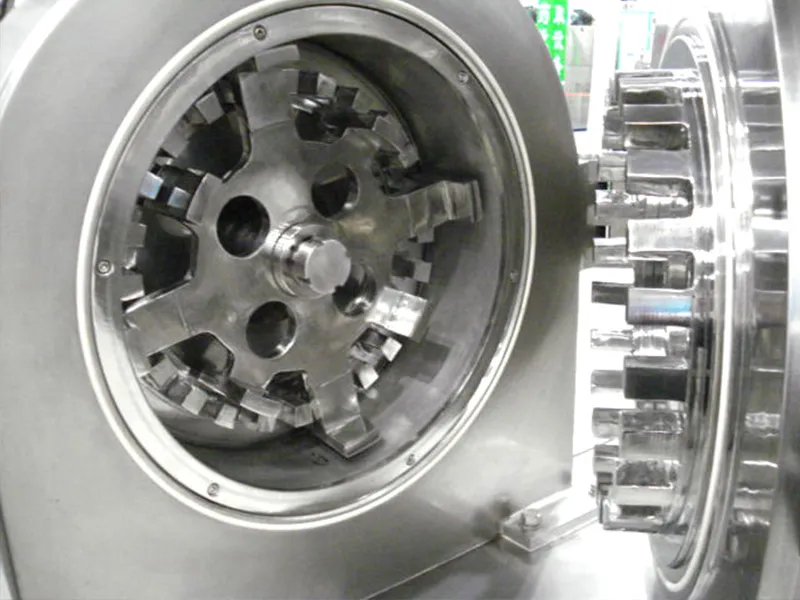

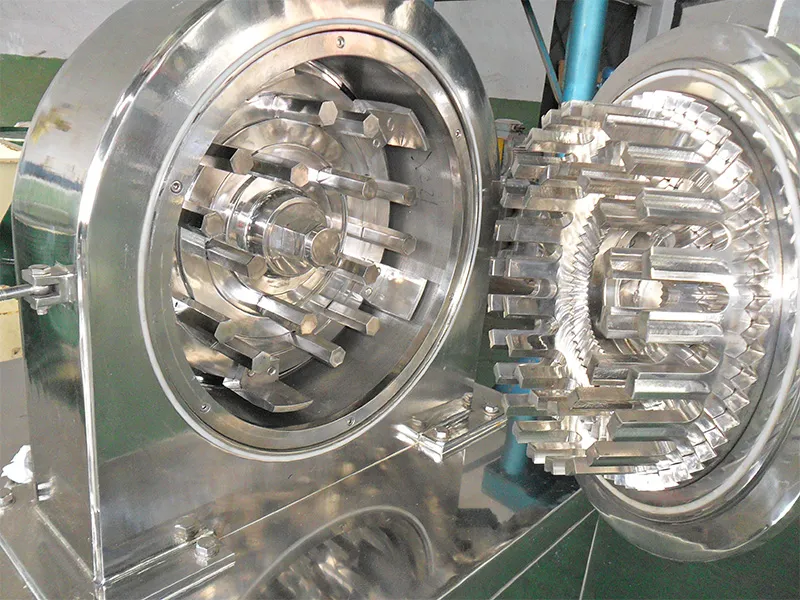

The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to various forces such as friction, shearing, and collision between the static disk and the ring gear, and is finally crushed. The crushing movable disk and static disk can be combined in different structures to meet the crushing requirements of different materials. The structural forms we currently design include: hammer type, pin type, turbine type, and grinding disc type.

Advantages

- Hammer type is suitable for pre-crushing and coarse crushing.

- The pin type is suitable for brittle, viscous and heat-sensitive materials.

- Turbine type is suitable for brittle materials and fibrous materials.

- The grinding disc type is suitable for tough and elastic materials,such as plastics.

- Hammer type and turbine type generally have a built-in screen to control the fineness of the product.

- Explosion-proof design can meet the crushing requirements of flammable, explosive and oxidizable materials.

- Low temperature design can meet the crushing requirements of heat sensitive materials.

- Different installation combinations are suitable for different process requirements;

- The motor can be connected with a belt to increase the speed, breaking through the problem that well-known motor brands do not have high-speed motors;

- Explosion-proof design can be selected to meet the ultra-fine grinding processing requirements of flammable, explosive and oxidizing materials;

- The design of high temperature, low temperature and normal temperature can be selected, with airtight circulation and inert gas circulation to meet the requirements of crushing temperature of different materials.