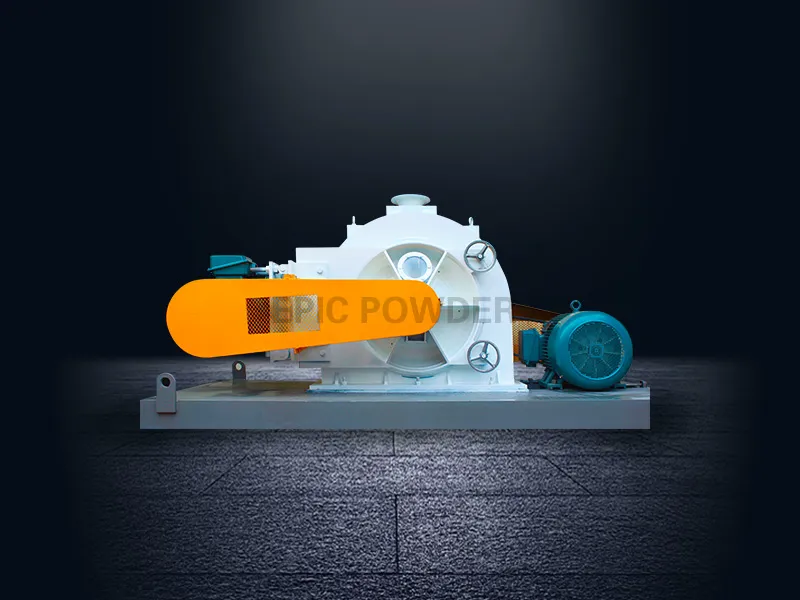

Working Principle and Equipment type features

The classifier and cyclone separator, dust collector and induced draft fan form a classifying system.

Under the action of fan suction, the material is moved from the lower inlet of the classifier to the classifying zone with the ascending airflow. Under the strong centrifugal force generated by the high-speed rotating turbine, the materials are separated and the fine particles which meet size requirements through the classifier impeller gap into the cyclone separator or the dust collector, the coarse particles entrained part of the fine particles collided with the wall and the velocity disappeared, descending along the cylinder wall to the secondary air outlet, and the coarse and fine particles were separated by the strong washing action of the secondary air. The fine particles rise to the classification zone for secondary classifying, and the coarse particles are lowered to the discharge port for discharging.

Product features

- Pintype crushing disc, no screen structure, fast speed, large capacity and low heat generation.

- Single power or double power can be selected, the line speed can reach up to 240m/s, strong impact force and shear force, and the product particle size is fine.

- It is suitable for dispersing and deagglomerating

- It is suitable for continuous high-speed mixing for ultrafine powder and liquid, and particle surface coating modification.

- It can be equipped with an air classifier to control the product fineness.

- Compact in structure, the mill is extremely easy to disassemble and clean.

Technical Parameters

| Type | Model | 250 | 400 | 500 | 630 | 800 |

|---|---|---|---|---|---|---|

| Coarse powder | Fineness(mesh) | 20 - 200 | 20 - 200 | 20 - 200 | 20 - 200 | 20 - 200 |

| speed(m/s) | 75 - 85 | 75 - 85 | 75 - 85 | 75 - 85 | 75 - 85 | |

| power(kw) | 7.5 | 18.5 | 22 | 37 | 55 | |

| Fine powder | Fineness(mesh) | 60 - 300 | 60 - 300 | 60 - 300 | 60 - 300 | 60 - 300 |

| speed(m/s) | 100 - 120 | 100 - 120 | 100 - 120 | 100 - 120 | 100 - 120 | |

| power(kw) | 15 | 30 | 37 | 55 | 75 | |

| Ultra fine powder | Fineness(mesh) | 100-2500 | 100-2500 | 100-2500 | 100-2500 | 100-2500 |

| speed(m/s) | 200-240 | 200-240 | - | 200-240 | 200-240 | |

| power(kw) | 15 x 2 | 30 x 2 | - | 55 x 2 | 90x 2 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.